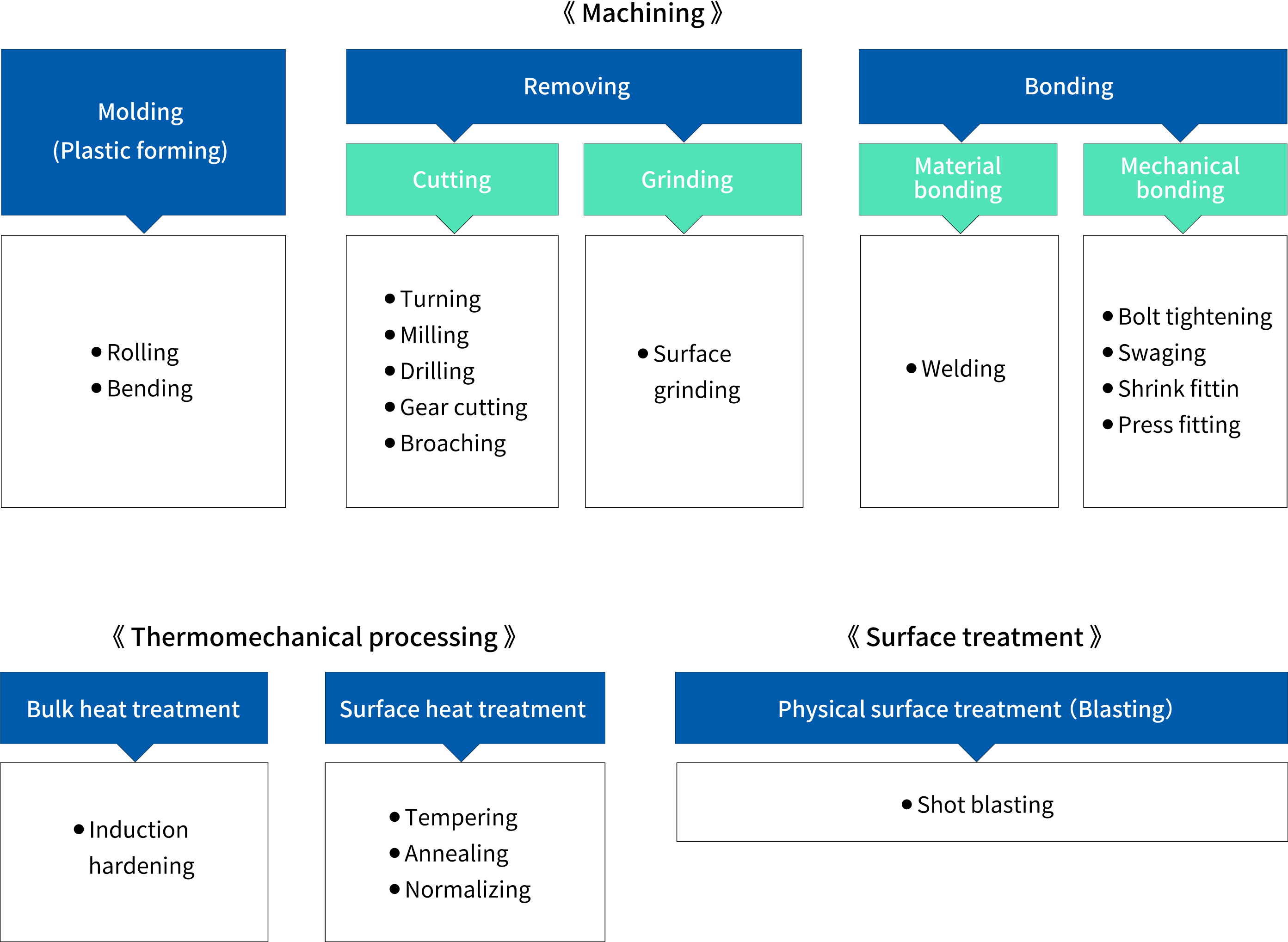

Processing Technology

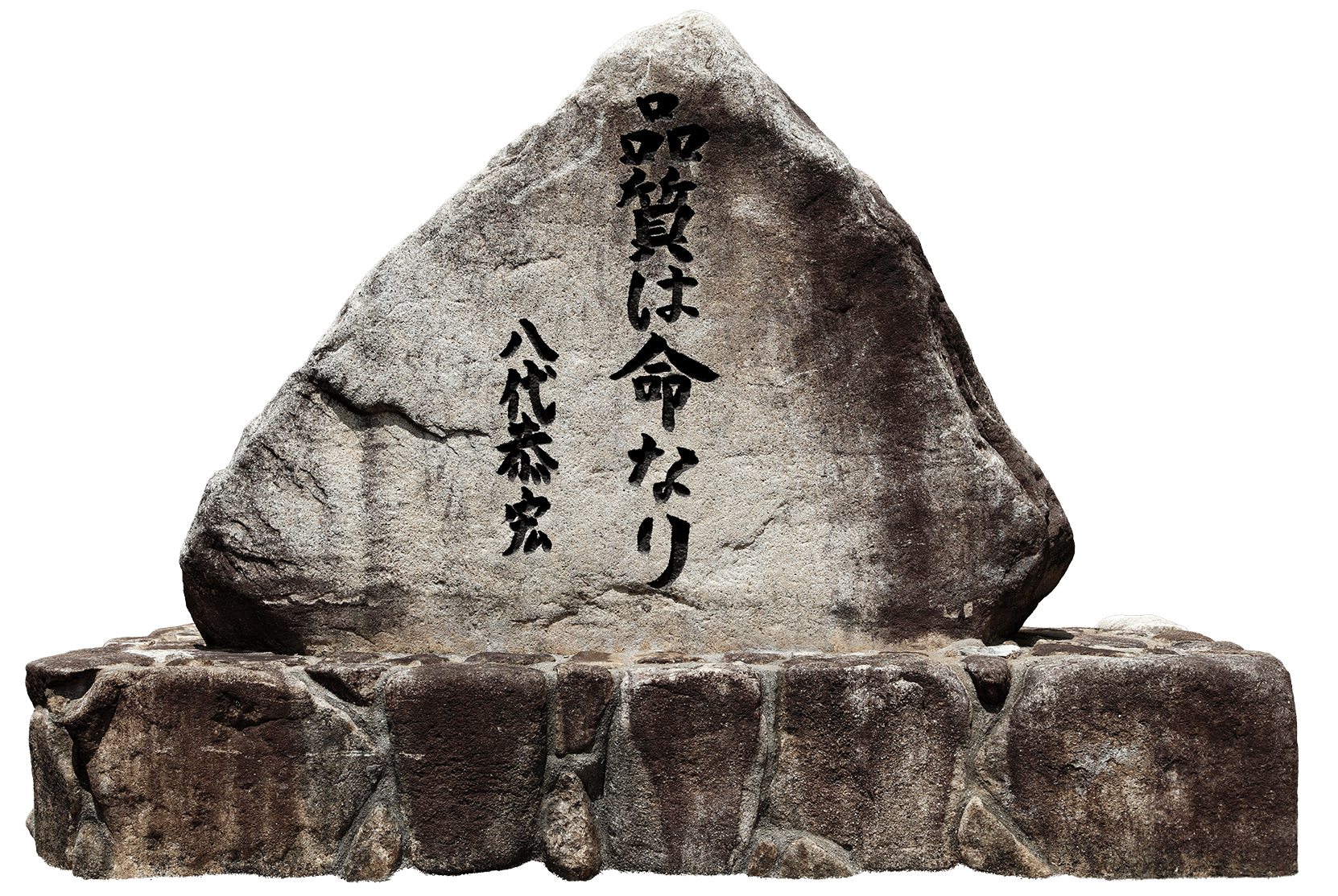

Quality is Vital.

“Quality is Vitality” These words were left behind by our second Chairman, Yasuhiro Yashiro, and form a psychological basis linking our group enterprises as a whole. Inheriting this maxim in perpetuity we are aiming to be a top global group by working untiringly for R&D and customer satisfaction.

What is the BENDA method?

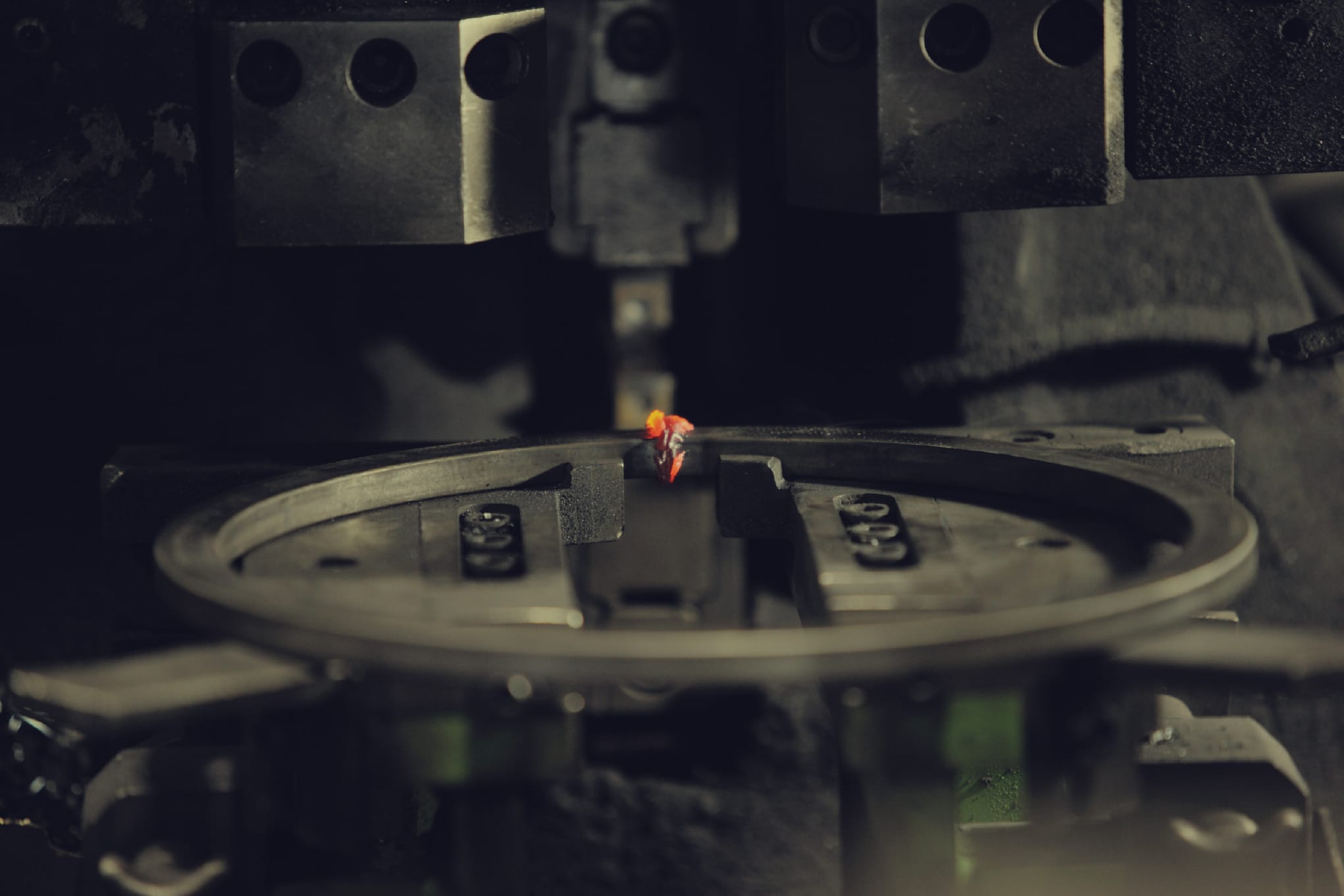

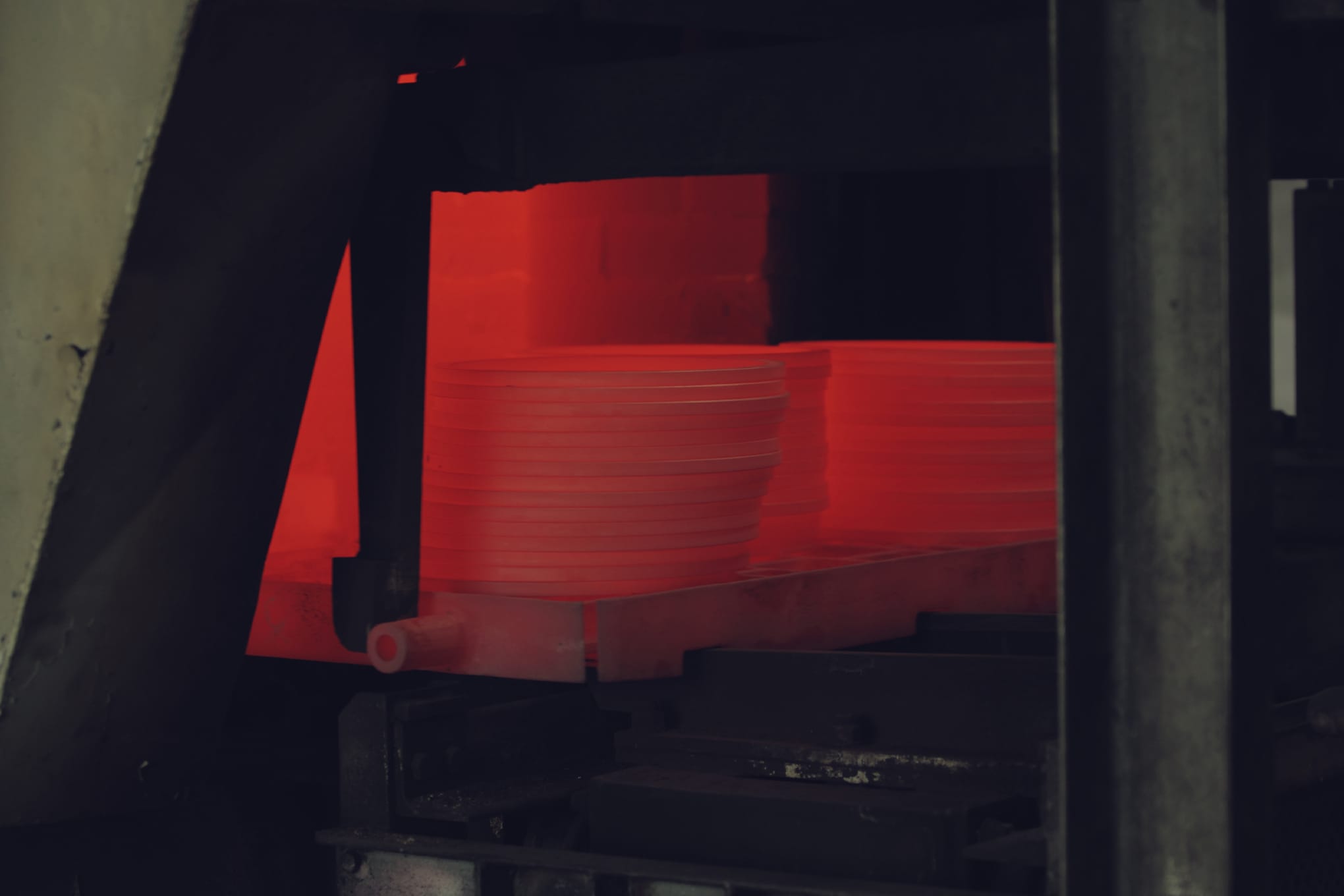

The Benda Method is a process for manufacturing metal rings using cold-bending processing, welding, and other technologies.

Round steel is cold-rolled into long steel material, bent into a predetermined shape, and then bent in layers to create a spiral. Then, each spiral is cut, welded, and formed into a perfectly circular ring. Refinements and improvements to this process over many years has led to the establishment of high-quality, high-yield metal ring manufacturing technology that produces an extremely small amount of material loss (scrap).

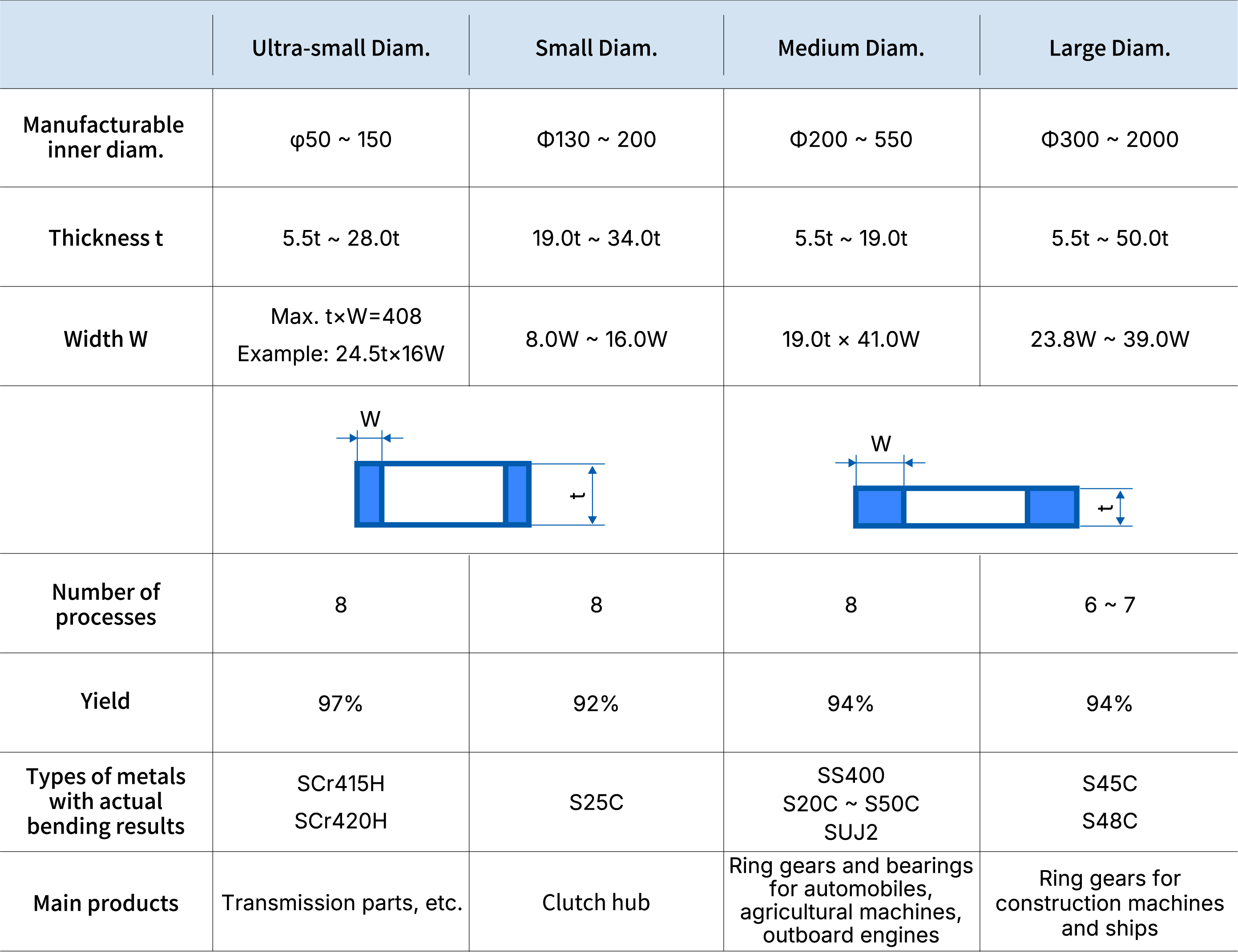

Benda Method Specifications

Technology Possessed by Benda Kogyo