Spreading made-in-Japan technology

across the world

Using unique technologies such as cold bending, welding, and heat treatment techniques,

we aim to deliver our metal ring manufacturing methods to the world.

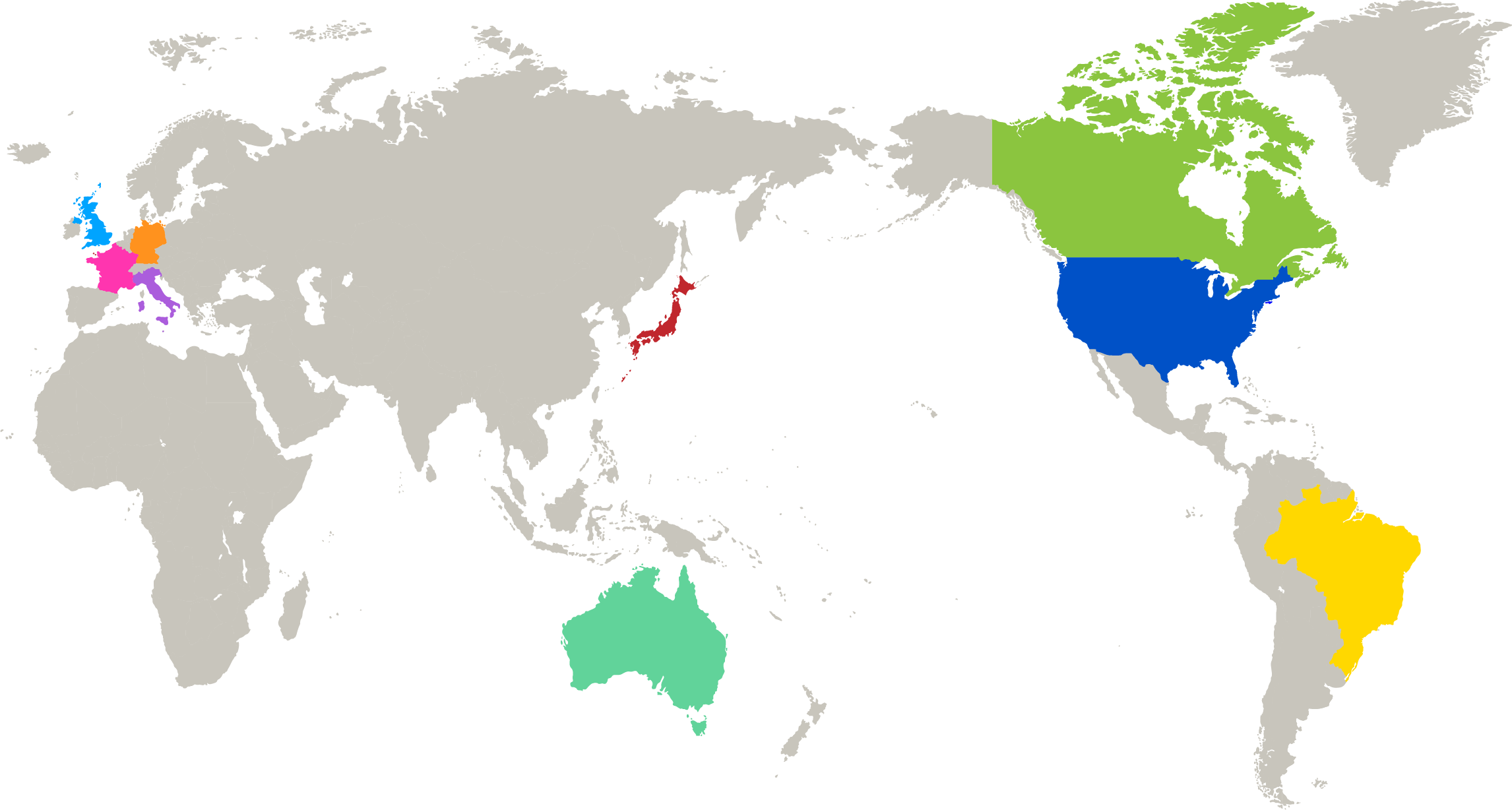

Based in Asia, we are expanding globally. By leveraging our greatest strength, the Benda method, we have established a leading market share in the field of ring gears. Additionally, as part of our new product lines, we have developed and commercialized small-diameter and large-diameter rings. At our Higashihiroshima Plant, established in 2007, we have expanded our business to include the production of rings for construction machinery and ships. While maintaining the quality of 'Made in Japan,' we ensure efficient production through centralized management at our production bases in Asia, including South Korea, China, and Thailand. Carrying on the pioneering spirit of 'Bending the world's steel!' from our founding days, we will continue to expand into fields beyond automotive applications and pursue further challenges.

- Benda Kogyo Co., Ltd.

President and Executive Director - Kazunari Yashiro

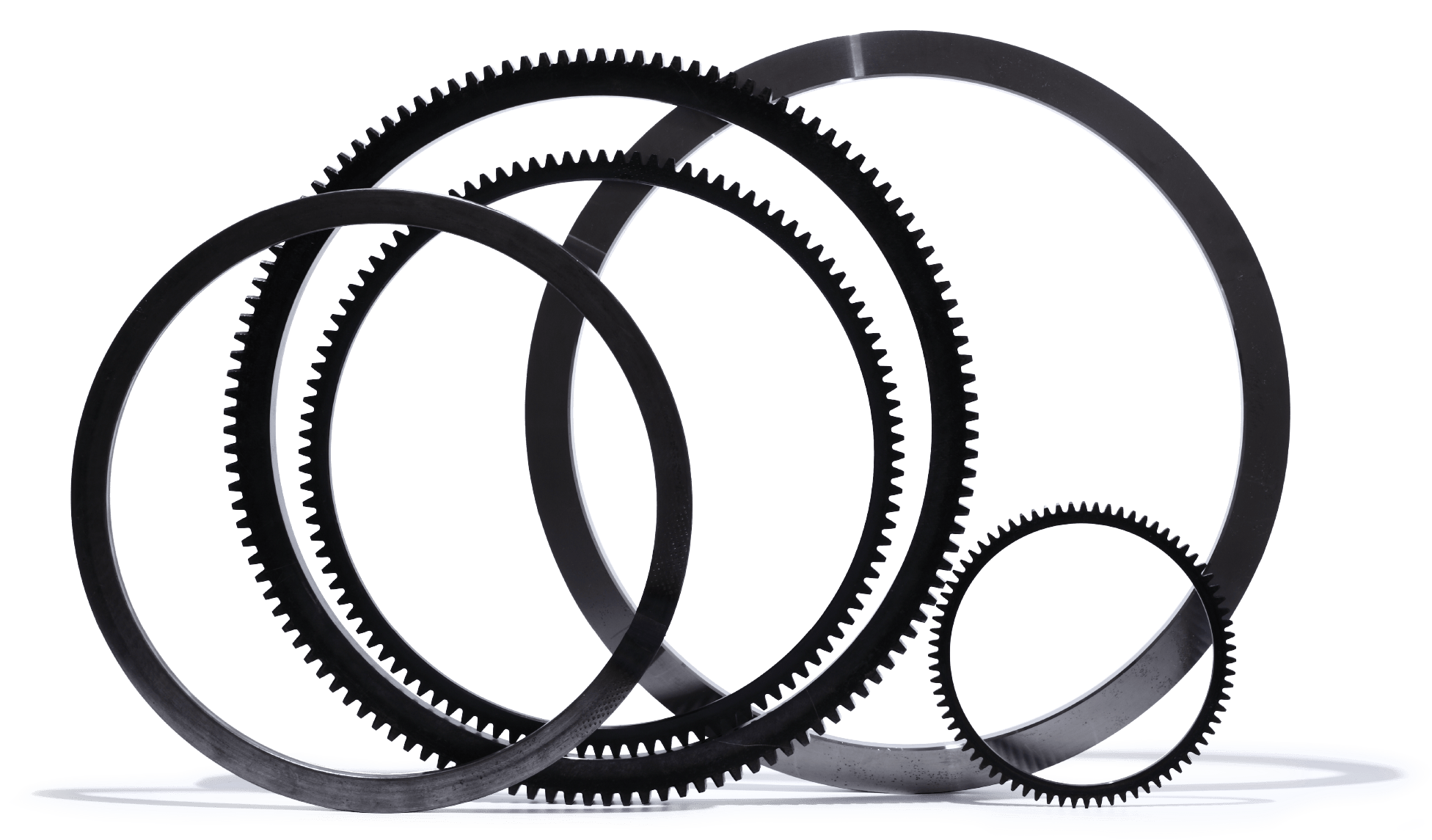

BENDA Method.

- Material yield

- %

Cold Bending Method drastically raised processability and productivity.

We received a request from a car manufacturer – “could you make it possible to mass-produce ring blanks by cold-bending processing?” The Benda Method came into being as a response to that request. With the press-punching method. 80% of the raw materials ends up as scrap. So we devised a method that cold-bends square steel material, then welds it. We also developed the dedicated equipment in-house.

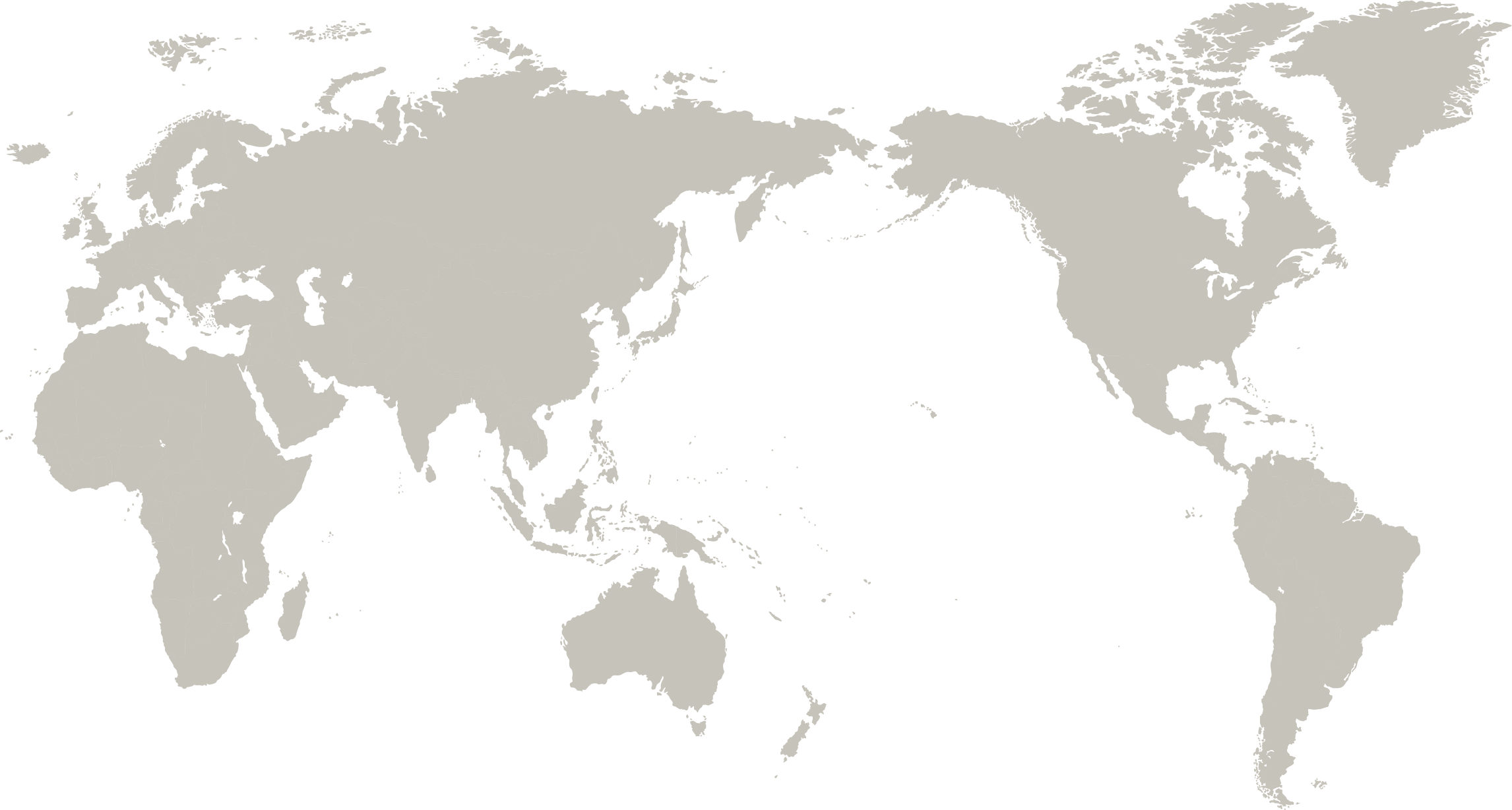

- Patents acquired in

- countries

across

the world

Top global share for engine starter ring gears.

In 1975 we acquired patents for a “Method and apparatus for fabricating metal rings” in nine countries across the world. Later we dubbed this The Benda Method. This was the occasion for us to withdraw from the business of bend-processing of general steel materials and specialize in ring products made by The Benda Method. With such products we subsequently rode the wave to motorization that hit Japan, and hove aimed ever since to become the top company for manufacture of starter ring gears used for automobile engines.

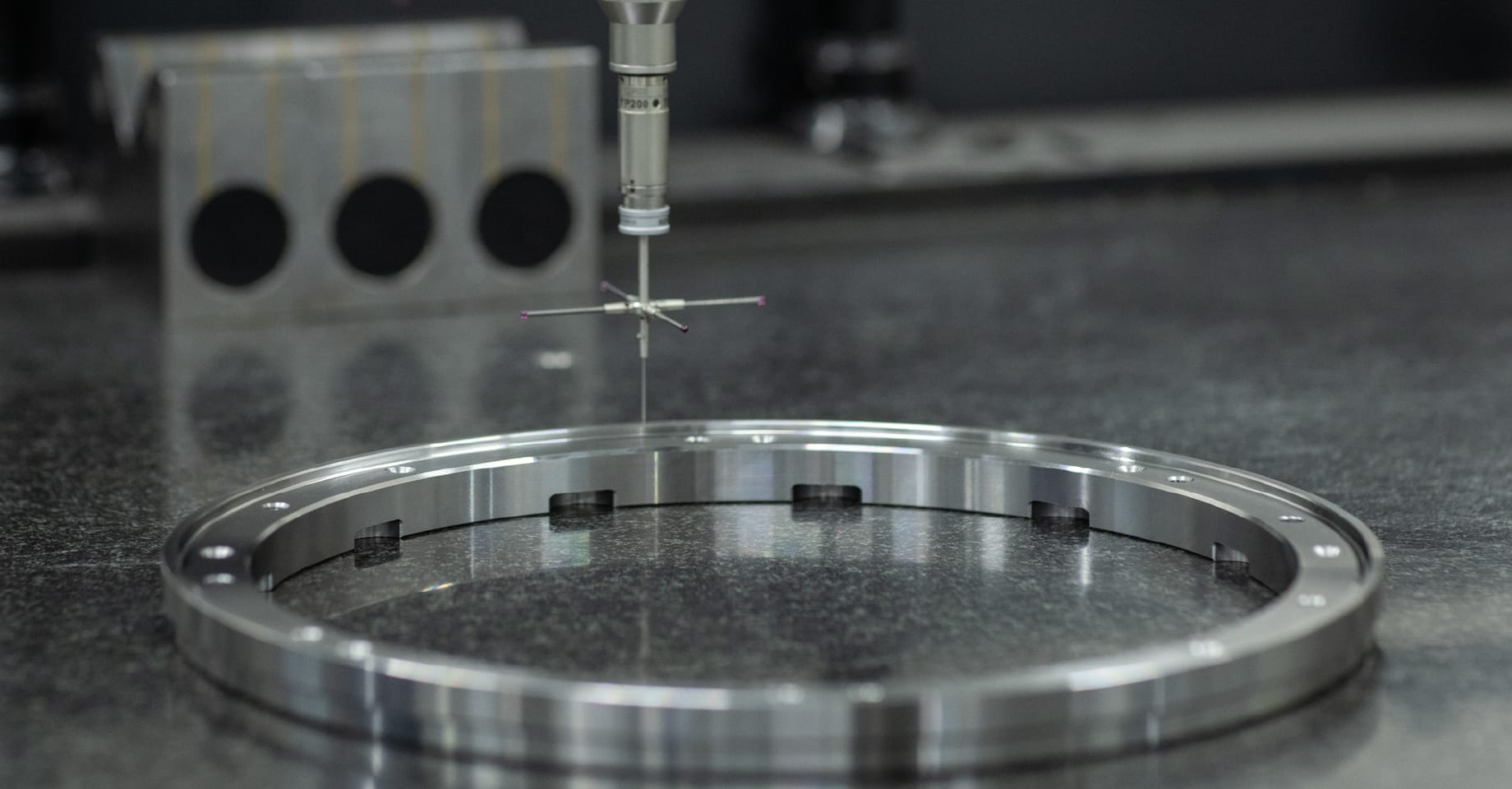

- Roundness

within - 0.mm

Won the Minister of Economy,

Trade and Industry’s Manufacturing Grand Prize in 2009.

The Benda Method’s advantages are high quality, high yield and low cost. With a raw material yield of 95%, it involves almost no material loss. The Benda Method is the fruit of successive improvements and innovations based on our motto “Quality is Vital”, and concentrates together our fine-grained expertise. In 2009 it received a Japanese Manufacturing Grand Prize from the Minister of Economy, Trade and Industry – the third such prize to be awarded.