2024

Yancheng Benda received the ‘Quality Excellence Award’ from CNC Corporation in Zhuhai , Guangdong , China. Among all of CNC’s partner companies in fiscal year 2023, Benda was recognized for its outstanding process evaluation and delivery quality.

2024

The commercialization activities of the visualization system advanced by Benda Engineering were commended for their potential contribution to the regional economic development.

2024

For the sixth year in a row, we were selected as an Excellent Health Management Corporation 2024.

2023

2023

For the fifth year in a row, we were selected as an Excellent Health Management Corporation 2023.

2022

2022

2022

In March 2022, CNC Company in Zhuhai of Guangdong , China appreciated us for our prompt response, delivery time and quality among companies participating in the new development.

2022

For the fourth year in a row, we were selected as an Excellent Health Management Corporation 2022. “Bright 500” is an award given to the top 500 companies out of 12,255 companies in the small and medium-sized corporation category in the “Excellent Health Management Corporation 2021” category, as “excellent companies among the excellent health management companies” and “companies that promote health management in the community”.

2022

Companies in Hiroshima Prefecture are commended for their efforts to actively engage in “health and productivity management” and achieve outstanding results that should serve as models for others. Efforts such as establishing an employee cafeteria and partially subsidizing the cost were appreciated.

2022

We were appreciated the reduction of material input weight and lathe processing man-hours by making ring gear end face non-turning, In February 2022, we received the Chief Enginnering Award from Yanmar Global Expert.

2021

2021

For the third year in a row, we were selected as an Excellent Health Management Corporation 2021. “Bright 500” is an award given to the top 500 companies out of 7,934 companies in the small and medium-sized corporation category in the “Excellent Health Management Corporation 2021” category, as “excellent companies among the excellent health management companies” and “companies that promote health management in the community”.

2021

Our policy on work style reform is to “promote diversity in work styles and aim to be a company with a good work-life balance while increasing added value and productivity”. Our efforts to introduce birthday leave system, telecommuting system, and counseling based on stress check results have earned us certification as a company that practices work style reform in Hiroshima Prefecture.

2020

For the third year in a row, Benda Sunkwang has received the 2020 GM Global Supplier Quality Excellence Award for a number of achievements related to product quality.

2020

In December 2020, Yancheng Benda received the 2020 Quality Excellence Award from YAMAHA MOTOR POWERED PRODUCTS.

2020

Continuing from last year, we were selected as a 2020 Certified Health and Productivity Management Organization.

2020

The Business Continuity Enhancement Plan is a system under which the Minister of Economy, Trade and Industry approves advance plans for disaster prevention and disaster reduction measures by small and medium-sized enterprises.

2020

Received the Certificate of Appreciation from Mazda Motor Corporation. We received the “Zero Defective Delivery for Six Consecutive Months” promotion award in January 2020 and the Quality Performance Excellence Award in March 2020.

2019

Continuing from last year, Benda Sunkwang has received the 2019 GM Global Supplier Quality Excellence Award for a number of achievements related to product quality.

2019

Based on our initiatives to tackle regional health issues and efforts to follow health promotion policies by Nippon Kenko Kaigi, we have been granted the status of a Certified Health and Productivity Management Organization, which puts us in a group of companies with exemplary health management policies.

2019

Benda Thailand received a Best Quality Award from Exedy (Thailand) Co., Ltd. We were commended for not receiving any complaints from our customers.

2018

We received this award for a number of achievements related to product quality, including the acquisition of the GM quality system certificate, acquisition of the IATF 16949 certificate, zero defects in the development process, zero defects on our production lines, zero complaints from customers, positive results of product quality audits, positive results of pre-shipping product quality audits, positive results of acceptance inspections, and the like.

2018

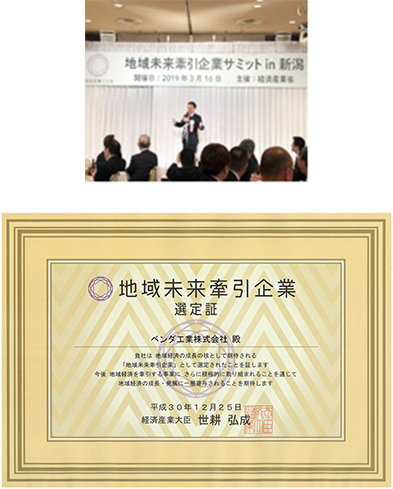

We have been selected as a Driving Company for the Regional Future, a status given to companies that have significant influence on the regional economic development as well as favorable growth prospects in the future, and carry out or are expected to carry out a central role in the value chain of the regional economy. Driving Companies for the Regional Future are selected according to an overall evaluation of their business transactions, hiring situation, sales volume, and other factors inside and outside a particular region. We also participated in the Driving Company for the Regional Future Summit held in Niigata.

2017

Yancheng Benda received a quality award for maintaining its defect rate at 0 ppm in products delivered to Subaru Corporation for three years in a row. In FY 2017, only two among a large number of suppliers received that award.

2017

We received a Supplier of the Year based on an overall evaluation of our product quality, prices, and delivery speed.

2016

Qingdao Benda received a GM China Supplier Quality Excellence Award for having the lowest rate of defective products delivered to GM China of all the suppliers in 2016.

2016

Benda Sunkwang received a Global Leading Company Award from KICOX (Korea Industrial Complex Corp.). The company was praised for its contribution to domestic industrial development achieved through an increase in exports, which was made possible by superb technological capabilities and unrivaled product quality.

2015

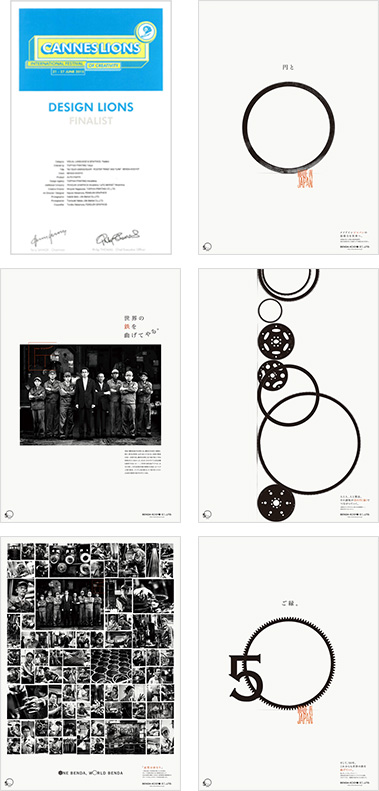

The “50th Anniversary Benda Kogyo Commemorative Posters (Series of 5 Posters)” designed by Benda Kogyo was selected for the Short List in the Design Division at the 62nd Cannes Lions International Festival of Creativity, the world’s most prestigious international advertising awards ceremony. Benda Kogyo, which celebrated its 50th anniversary in 2014, is proud to have attained the top global share for ring gears for automotive parts. We are a global corporation that is expanding production in South Korea, China (Qingdao and Yancheng), and Thailand. While planning this promotion for the 50th anniversary of Benda Kogyo, the Toppan Idea Center (Hiroshima), which is our company’s planning and design organization, used the theme of “harmony” to express our commitment to providing perfectly circular ring gears to various countries around the world.

Their creative designs used the beauty of our perfectly circular products to symbolize harmony, while also synchronizing the 50 years of history forged by our craftsmen in a series of 5 posters. The overall effect expresses the strong spirit and reliability that Benda Kogyo infuses into each manufacturing process. We are confident that the selection of these works for the Short List are a result of Benda Kogyo’s made-in-Japan quality, craftsmanship, and harmonious spirit resonating with people all around the world.

2015

Benda Kogyo was selected as one of the Ministry of Economy, Trade and Industry/Small and Medium Enterprise Agency “Small Businesses Top 300” that activate the local economy and expand aggressively to overseas markets, through innovative product development and provision of creative services.

2015

Our 2015 calendar, which features Benda Group craftsmen from domestic and overseas locations throughout the world, received high praise at the 66th All Japan Calendar Competition where it won a prize from out of 658 entries from throughout Japan.

2014

As a mid-size enterprise that takes on groundbreaking challenge, we recieved manufacturing subsidies from the Small nad Medium Enterprise Agency.

2013

We won an incentive award for our small- and large-diameter manufacturing technology in the Excellence Awards for New Technologies and Products.

2012

We received a Perfect Quality Award for a perfect product quality score (i.e., no defects) until 2011.

2009

Since the founding of our company, we have been working on the development of cold-bending processing for steel. We have a substantial track record in this field, such as the use of Benda Kogyo bending technology on H-section steel material for use in tunnels throughout Japan. In the early 1970s, we started the development of continuous mass production technology for ring blanks (material for ring gears). The existing method had many problems regarding production efficiency. Therefore, we developed a replacement method that featured a unique combination of cold bending and electrical resistance welding on square steel rods. In 1975, we were granted patents in 9 countries for “method and apparatus for manufacturing metal ring material”. We called this the “Benda Method”, and put it to use for the full scale production of automotive parts. Currently, we are manufacturing a wide variety of rings, from 10cm diameter rings for lawn mowers to 1m diameter rings for ships and construction machines.

2009

In 2009, we were interviewed by the then Director Nagao of the Chugoku Bureau of Economy, Trade and Industry.

2009

In March 2009, we won the Ministry of Economy, Trade and Industry’s Outstanding Performance Award in “Small and Medium Business IT Management Awards 2009” and the “IT Coordinators Association President’s Award”. Regarding the use of IT, Benda Kogyo was recognized for the aggressive utilization of external experts (IT coordinators).

2008

Benda Kogyo was certified as a “Company (Organization) Practicing IT Management” by the Bureau of Economy, Trade and Industry. IT management refers to a management style in which IT is utilized at an advanced level in order to achieve management strategies and innovation.

2008

In 2008, Yancheng Benda acquired ISO/TS16949 certification.

The quality of its manufacturing had been recognized as nothing inferior to Japan’s.

2003

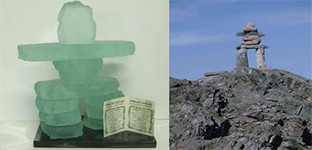

We received this “inuksuk” from Magna International, a major automotive parts manufacturer in Canada. These objects are a symbol of friendship. Inuksuk are made by stacking rocks in the shape of a person. They are used as points of reference or markers along travel routes, and are commonly found in the Arctic region. They play an important role when snow blankets the ground and covers all other points of reference. It is said that travelers could peer through the hole in the center to look for the next inuksuk, and thereby figure out the correct course of the road.

2000/2001

Benda Kogyo’s products received a quality promotion award from Mitsubishi Fuso Truck and Bus Corporation for their superb quality.